Electrostatic Separation System for Rigid Plastic Recycling

Electrostatic Separation System for Rigid Plastic Recycling

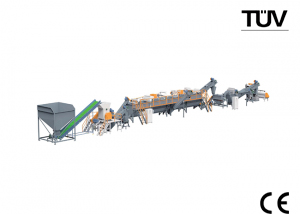

Armost’s Electrostatic Plastic Separation System is a high-efficiency, multi-stage recycling line designed to purify rigid plastic flakes by removing contaminants such as films, rubbers, and mixed plastics. Engineered for WEEE, ELV, PVC window profiles, and HDPE/PP recycling, this system ensures maximum material value recovery.

Key Separation Technologies:

-

Airflow Separator: Removes flexible impurities (labels, films, dust) using zig-zag air separation.

-

Rubber Separator: Effectively removes rubber and elastomeric impurities from the plastic stream.

-

Electrostatic Separator: Precisely separates plastics with similar densities but different electrical properties (e.g., ABS/PS, PVC/PE).

Drying & Adaptive Design:

The line integrates multiple dryers to handle environmental, seasonal, and batch moisture variations. This ensures consistently dry material—essential for reliable electrostatic separation.

For the electrostatic separation process, by adopting a 3-stage separation design with middling return and dedusting system, our electrostatic separation system separates rigid plastic to high purity while also maintaining a high processing capacity.

The system is custom designed based on different material composition, enabling the system to separate up to 4 kinds of plastics.

The Electrostatic Separation System, under the name Intelligent Mixed Plastic Separation System, won the Ringier Innovation Awards in 2016 and 2017.

As the industry leader in WEEE/ELV waste plastic recycling and separation, Armost has deep understanding of the plastic recycling process and key technical details in plastic recycling equipment design. As a result, we are able to continuously innovate and improve our equipment. Armost was the Winner of the Ringier Innovation Awards in 2016 and 2017. We currently hold more than 15 patents and is recognized as a National Innovation Enterprise in 2023.

—————— Our company has advanced equipment ——————

—————— Excellent technical team ——————

—————— Production technology ——————

We give prompt feedback upon receiving inquiries from customers. We will provide our customers with customized solution after evaluating the specific material state, capacity requirements, limitations and challenges at their production site etc. We believe in running an honest business and look to become long-term partners and friends with our customers by providing our best services.

Our partners think highly of us.